| 项 目 | 技术参数 |

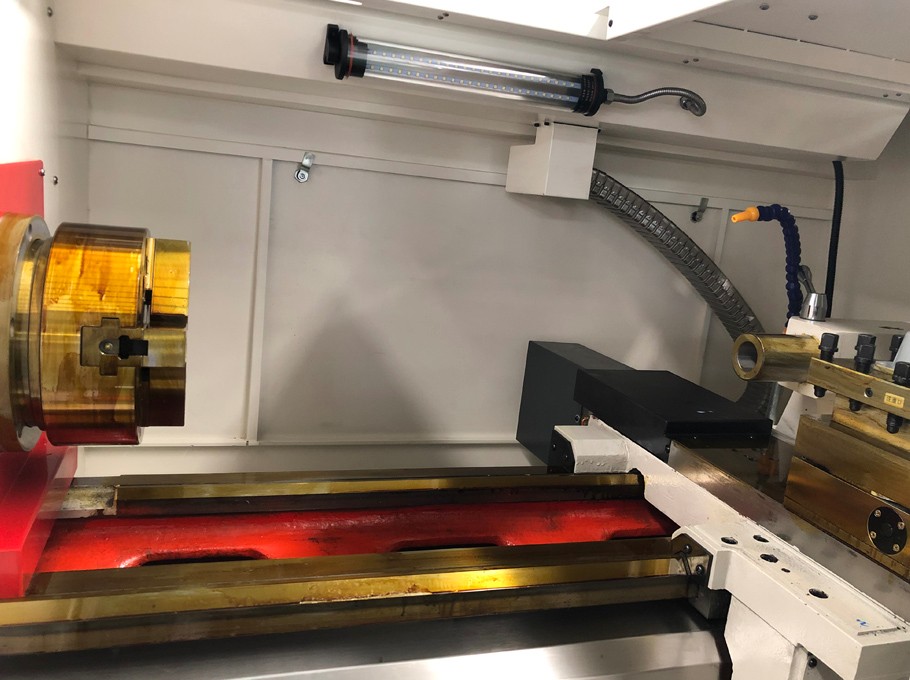

| 床身上大工件回转直径 | Φ500mm |

| 拖板上大工件回转直径 | Φ290mm |

| 大工件长度 | 1000/1500mm |

| 主轴转速范围 | 3档, 25~1600rpm |

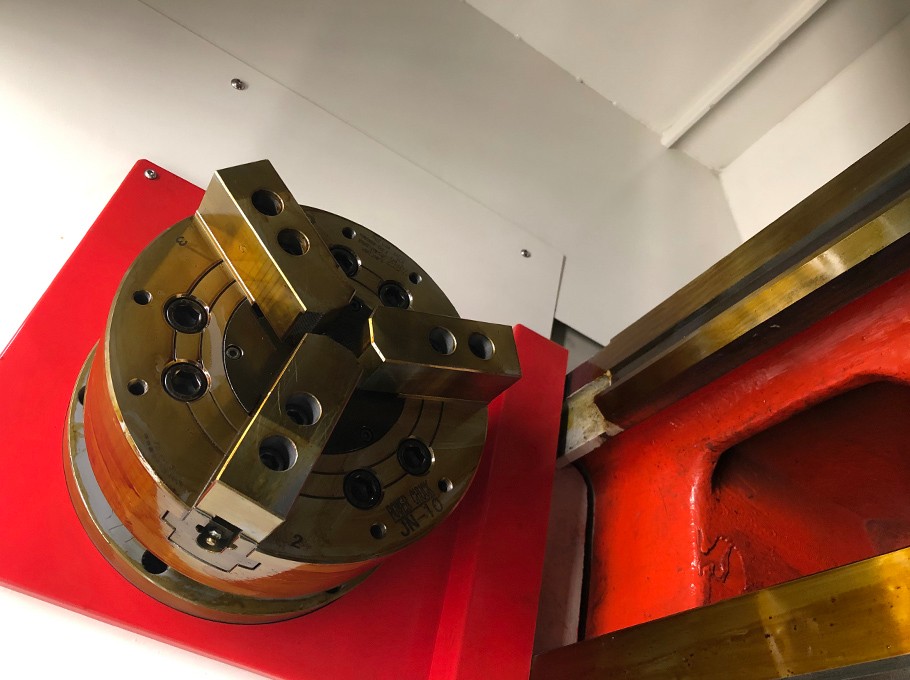

| 主轴通孔直径 | Φ82mm |

| 导轨宽度 | 390mm |

| 主轴头形式 | D-8 |

| 主轴内孔锥度 | 1:20 |

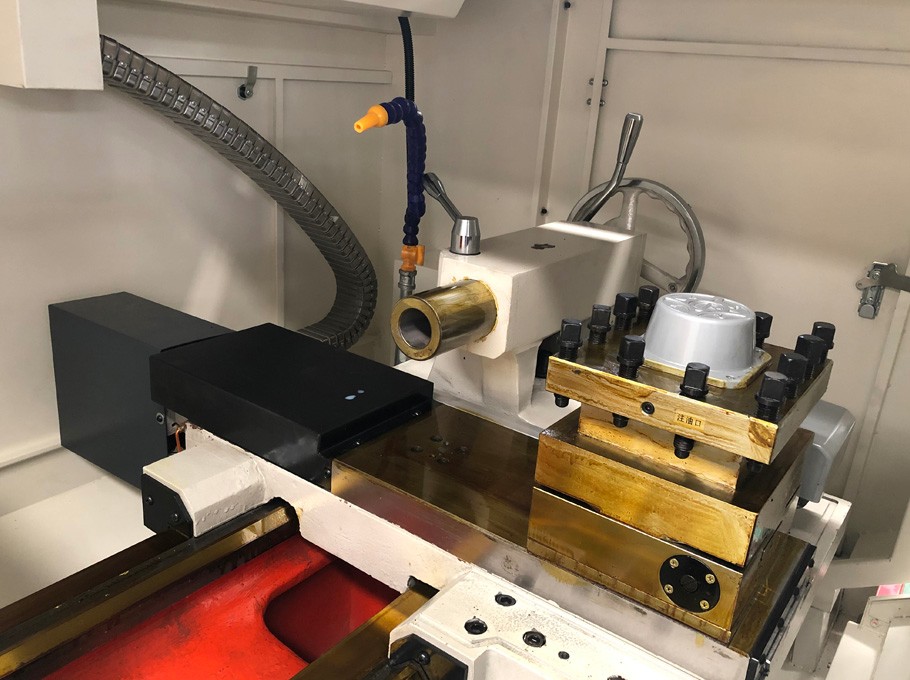

| 刀架刀位数 | 4工位电动刀架 |

| 刀具截面规格 | 25mm×25mm |

| 电机小设定单位 | (Z) 纵向 0.001mm,(X) 横向 0.001mm |

| 刀杆快进速度 | (Z) 纵向 10m/min, (X) 横向 8m/min |

| 尾座套筒内孔锥度 | MT5 |

| 尾座套筒大移动距离 | 150mm |

| 主电机功率 | 7.5KW |

| 车床净重约 | 2700kg |

2、数控车床ck6150主要特点

1、 24级齿轮变速,车削扭矩大,加工效率高、精度高,。

2、 主轴加大孔径φ82mm。

3、 床身宽度420mm。

3、数控车床ck6150主要配置

⑴ 控制系统 :广数GSK ⑵ 卡盘可选:手动、气动或液压卡盘等。

⑶ 尾座可选:手动

⑷ 电动刀架 :立式四工位

⑸ 润滑配置:自动机油润滑系统。

4、数控车床ck6150用途

本机床可广泛用于阀门/水暖/汽车零配件及其它五金零件的精加工,可实现多种产品的外圆/端面/内孔/切槽/任意锥面/球面和各种公英制螺纹的自动切削

| Model parameters | CJK6136 | CJK6140 | CKA6150 |

| 1. Maximum cutting diameter (mm) | 360 | 420 | 500 |

| 2. Maximum turning diameter on skateboard (mm) | 180 | 220 | 280 |

| 3. Maximum workpiece length (mm) | 750/1000 | 750/1000 | 1000 |

| 4. Maximum cutting length (mm) | 680/870 | 680/870 | 930 |

| 5. Chuck size (inches) | 8 | 10 | 10 |

| 6. Spindle type | A2-6 | A2-6 | A2-8 |

| 7. Diameter of spindle inner hole (mm) | Φ60 | Φ60 | Φ82 |

| 8. Tail socket travel (mm) | 130 | 130 | 150 |

| 9. Diameter of tailstock sleeve (mm) | Φ65 | Φ65 | Φ75 |

| 10. Spindle speed (rpm) | 2500 | 2500 | 2000 |

| 11. Fast moving speed X/Z (m/min) | 4/8 | 4/8 | 4/8 |

| 12. Maximum stroke of X-axis (mm) | 250 | 250 | 280 |

| 13. Maximum Z-axis travel (mm) | 875 | 875 | 935 |

| 14. Number of job positions | 4 | 4 | 4 |

| 15. Tool change time (single station) s | 2.4 | 2.4 | 3 |

| 16. Knife handle size (mm) | 20×20 | 25×25 | 25×25 |

| 17. Spindle motor power KW | 5.5 | 5.5 | 7.5 |

| 18. Servo motor torque X/ZNm | 4/6 | 4/6 | 5/7 |

| 19. Machine weight (kg) | 1950 | 1950 | 2600 |

| model | CJK6150 | |||

| Guide rail form and screw | Hard rail | ball screw | ||

| ● | ● | |||

| spindle | Three speed frequency conversion | domestic | NSK bearings | |

| ● | ● | o | ||

| tailstock | Manual socket tailstock | Hydraulic sleeve tailstock | Pneumatic sleeve tailstock | |

| ● | o | o | ||

| Dota | Vertical four station external cooling electric knife tower | Vertical four station internal cooling electric knife tower | Horizontal six station electric turret | Horizontal eight station electric knife tower |

| ● | o | o | ||

| Chuck/oil cylinder/fixture | Manual chuck | Φ 250mm/10 inch hollow hydraulic chuck | Φ 250mm/10 inch solid hydraulic chuck | |

| ● | o | o | ||

| CNC system | FANUC0i-TF | Guangzhou CNC 980TC3 | other | |

| o | o | o | ||

| Hydraulic components | Wuxi Bailang | |||

| ● | ||||

| Chip removal | Chip collecting tray | |||

| ● | ||||

| cooling system | Cooling pump and water tank | Fan electrical cabinet | Electrical cabinet constant temperature air conditioner | Electrical cabinet heat exchanger |

| ● | ● | o | o | |

| other | Machine lighting fixtures | machine tool isolator | ||

| ● | o | |||

| Technical Documentation | steady rest | follower rest | ||

| ● | o | o | ||

If you have any suggestions for our products or services, please leave me a message in a timely manner!

Contact us is the way to solve the problem